Cutting Pockets in Panels – which machine is best?

When our customers decide to up their game and use Castle machines for pocket joinery on panels – for cabinet carcasses and furniture, built-ins and other custom pieces – we’re…

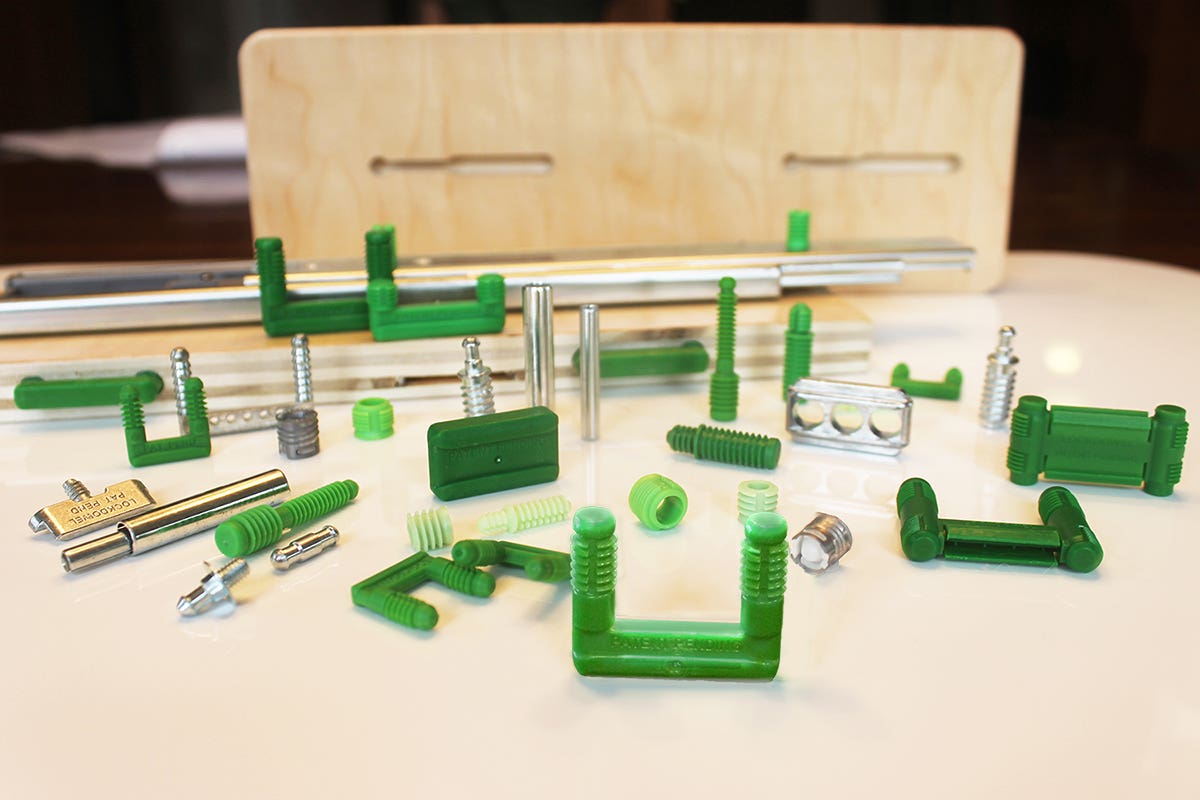

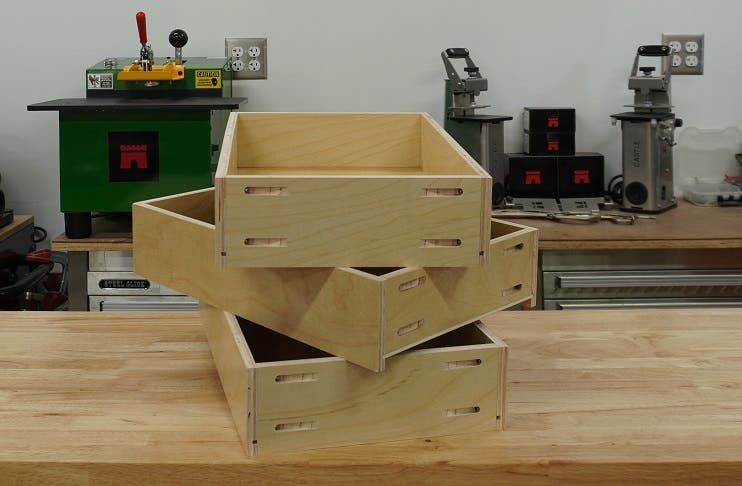

When our customers decide to up their game and use Castle machines for pocket joinery on panels - for cabinet carcasses and furniture, built-ins and other custom pieces - we’re sometimes asked which machine is best for their shop. The short answer is that every single Castle machine can be used for pocket joinery in panel material. The longer answer is more a series of questions we ask them, to help determine which machine is best for their process: Do you have shop space limitations? Are your panel sizes relatively small or are they larger? Will your operators need both hands free for handling the panels? Will you be cutting pockets occasionally, daily, hourly, or continuously?

In this video, Castle USA’s Phil Johnson demonstrates the advantages of the benchtop TSM-12 Pocket Cutting Machine and the stationary, foot-pedal-operated TSM-22. Both of these machines are virtually “plug-and-play,” and both use standard 110V electric. Which one would be right for your shop’s panel work?

Castle USA

800.282.8338

www.CastleUSA.com

Prod URL: TSM-22 Pocket Cutter Machine

Sales@CastleUSA.com