A Superb Finishing Touch

At AWFS in Las Vegas last year, Gibbs Group NA introduced its new Cup Brush Sander to the North American market. The machine eliminates almost all hand sanding of cabinet…

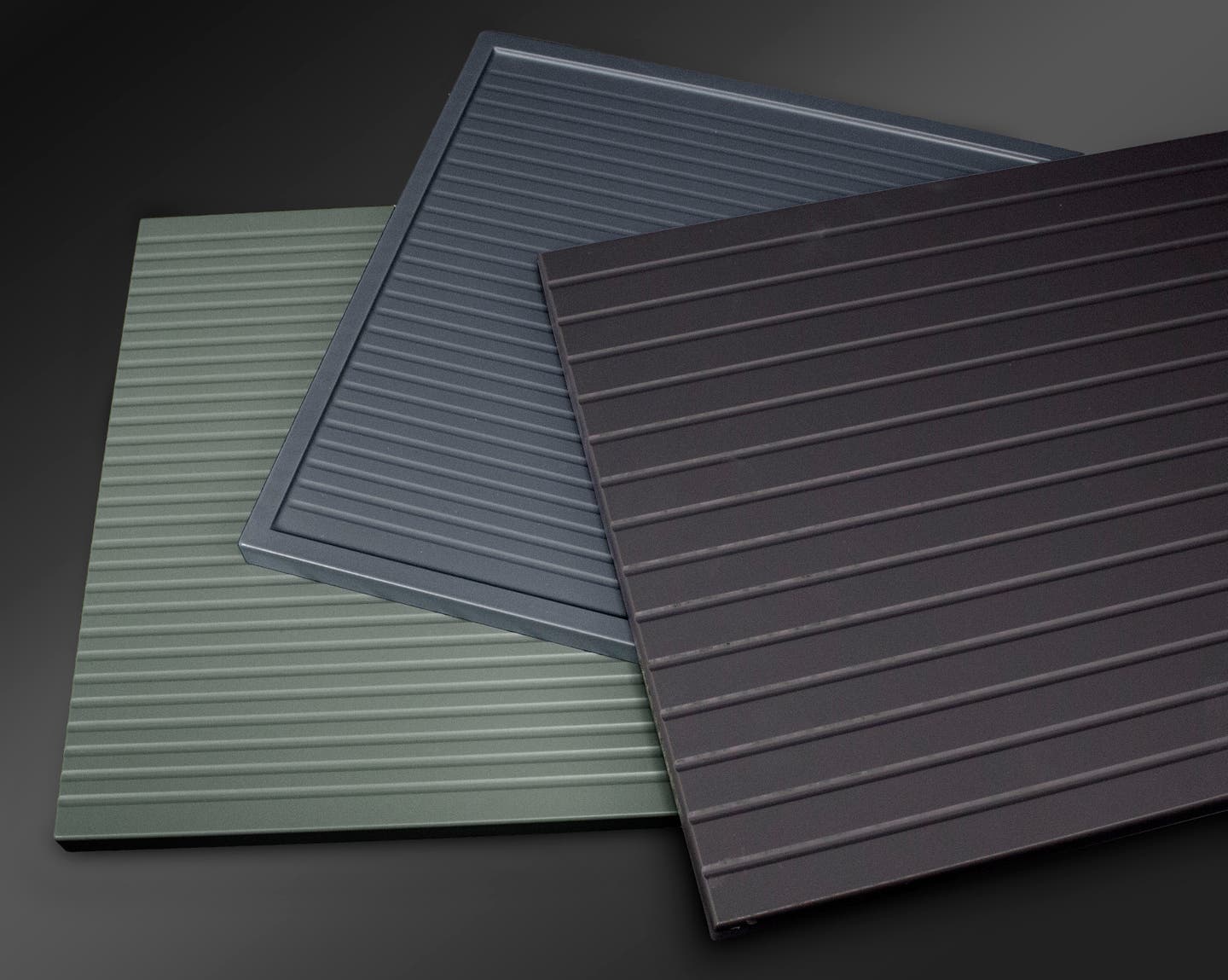

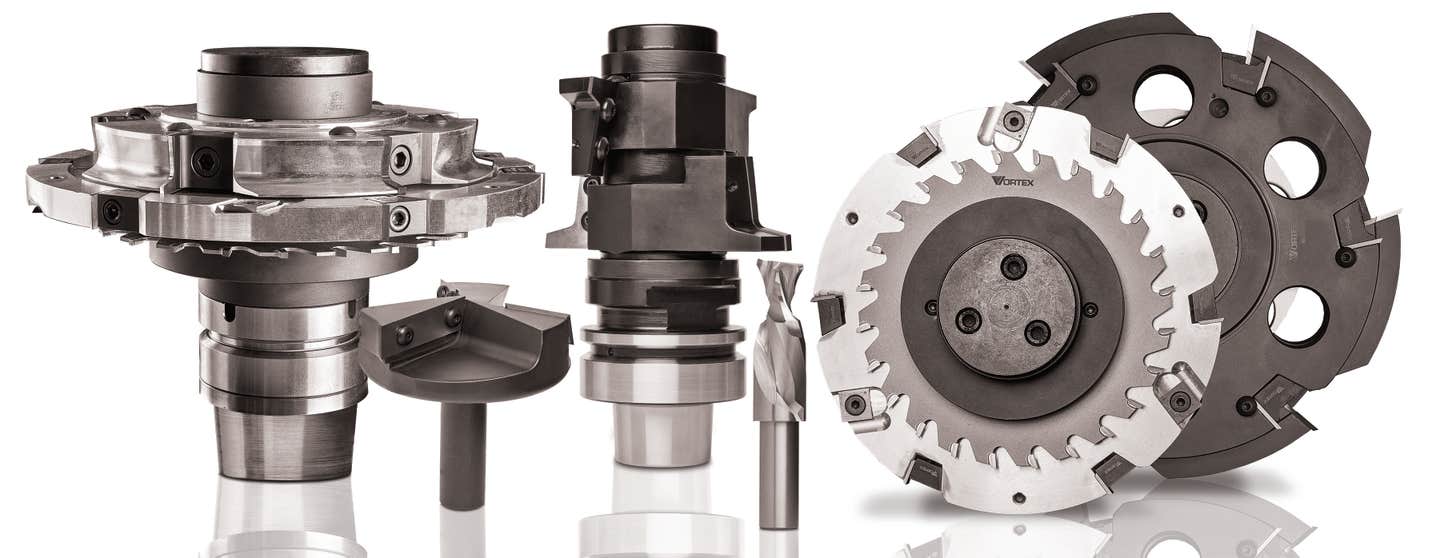

At AWFS in Las Vegas last year, Gibbs Group NA introduced its new Cup Brush Sander to the North American market. The machine eliminates almost all hand sanding of cabinet doors, drawer fronts and other components after machining, and prior to coating. Using cup-style brush heads in denibbing machines is not a new concept, but when the technology is adapted exclusively for finish sanding, the results are both consistent and impressive.

The new machine’s robust construction supports its ability to perform the most delicate of sealer sanding tasks, while it also handles a wide range of general sanding duties. It uses Gibbs’ unique 360-degree brush surface sanding technology, and offers easy and low-cost brush and abrasive replacement. The Cup Brush Sander is easy to operate using a touchscreen control with six customizable programs for easy and fast changeovers. And there’s a built-in automatic cleaning function that leaves doors and drawer fronts dust-free and ready to coat. Various models of the Cup Brush Sander are available to accommodate different woodshop space and throughput needs.

In addition to the Cup Brush sander, Gibbs Group NA also offers its Woodwelder to North American woodshops. This is a portable radio frequency machine that is capable of setting glue joints in 15 seconds or less. It works with standard PVA and UREA glue, and while it can be used for many applications that use water-based glue, its most common application is assembling cabinet doors and boxes.

Gibbs Group NA is located in Georgia. The company also offers a full line of drying racks and spray tables, and all of its equipment is built in the UK. If catalog items don’t quite fit a woodshop’s needs, the team at Gibbs is happy to discuss custom design changes.

Gibbs Group NA

a.staalner@gibbsgroupna.com

877-785-0274

gibbsgroupna.com