Aubin Woodworking increases efficiency with Swiss powerhouses STRIEBIG and Lamello

Aubin Woodworking in Bow, NH is a 50-employee, 26-year commercial millwork company housed in a 20,000 square foot facility, with President Tony Aubin at the helm. To facilitate his company’s…

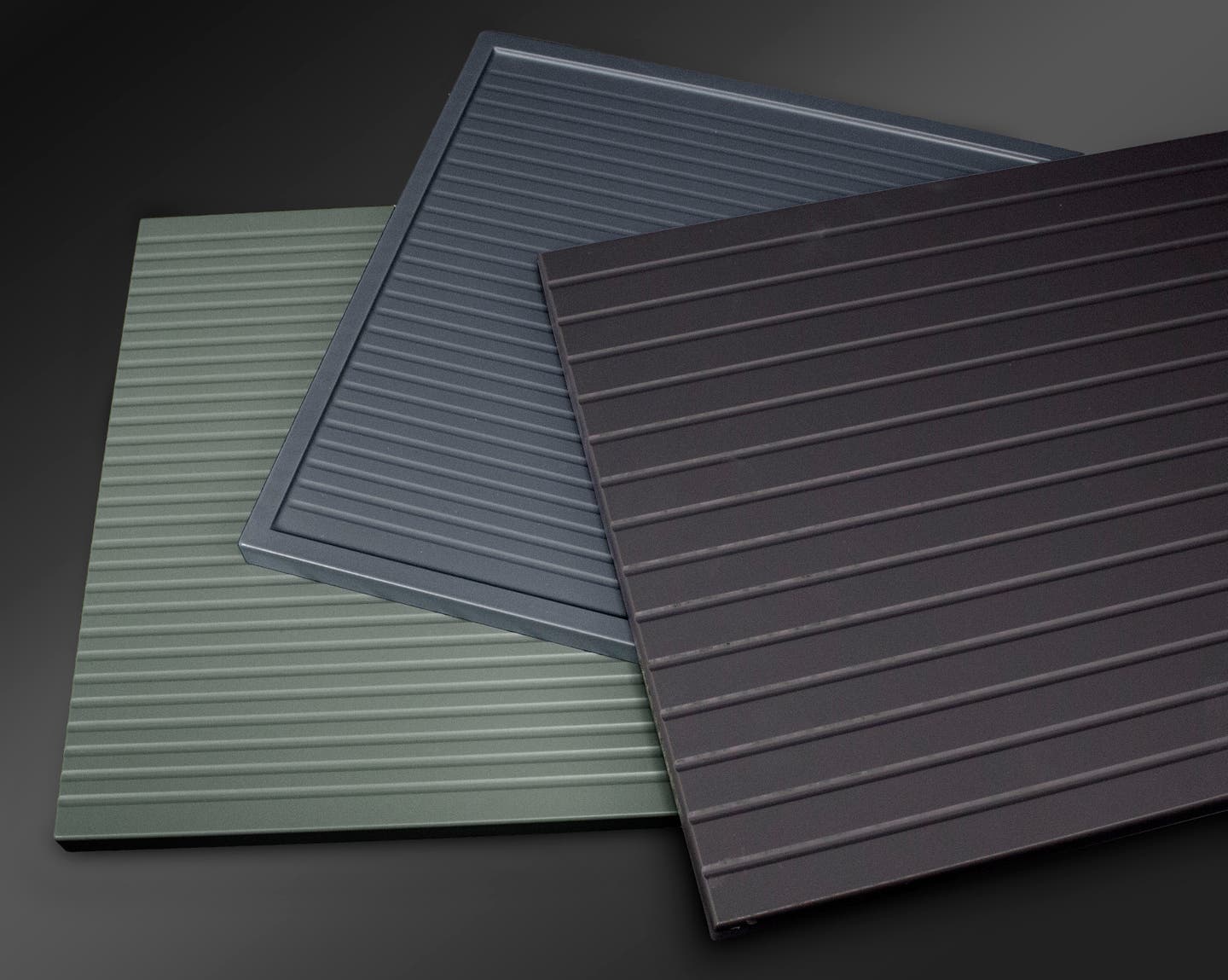

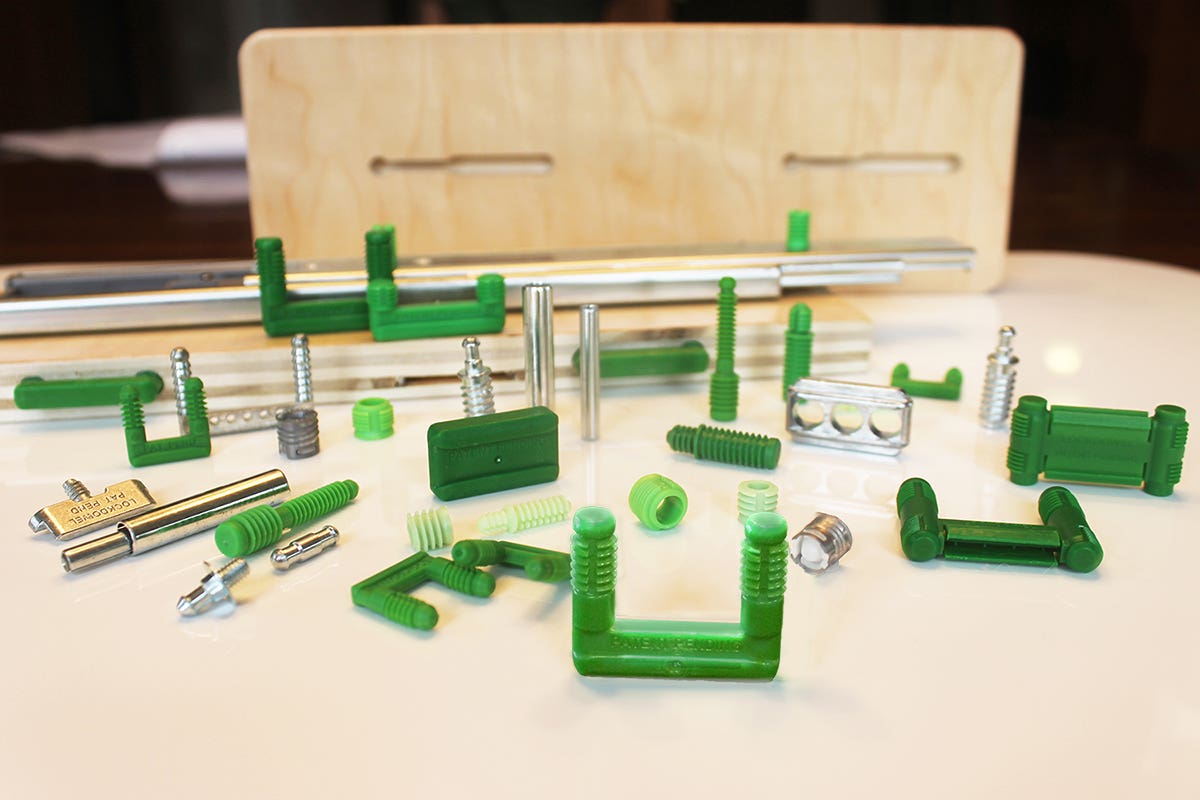

Aubin Woodworking in Bow, NH is a 50-employee, 26-year commercial millwork company housed in a 20,000 square foot facility, with President Tony Aubin at the helm. To facilitate his company's growth, he's not only built relationships with general contractors throughout New England, he's also looked to improve processes by adopting machinery and systems that make work easier on his team, create more accurate and repeatable products, and increase shop efficiencies. To achieve that goal, Aubin invested in STRIEBIG vertical panel saws and Lamello joinery systems, both imported by Colonial Saw Company.

Striebig Vertical Panel Saws

Aubin used a Striebig vertical panel saw as his primary panel processor prior to buying his first nested-base CNC router, and now a combination of the two machines has created a very efficient duo.

“I can probably do three times as much in a day combined with the CNC router and the Striebig” as opposed to using only a router, claimed Aubin (now on his third Striebig saw). Simple parts like shelves and backs are obvious applications where the vertical panel saw allows the CNC router to run more productively. “We’ll take as much rectilinear material and put it on the Striebig, making straight cuts and cross cuts. It’s all been optimized already in the software to run on a panel saw instead of the router,” he explained.

However, using a Striebig also improves efficiencies at the edge-bander as well.

Colonial Saw

781-585-4364

www.csaw.com

IWF Booths 5545 and 5542