How to Economically Increase Factory Volume at a Small Shop

Gearing up for the next level of production isn’t just about machines: it also needs to address the software that makes those machines work most efficiently, and profitably.

Gearing up for the next level of production isn't just about machines: it also needs to address the software that makes those machines work most efficiently, and profitably.

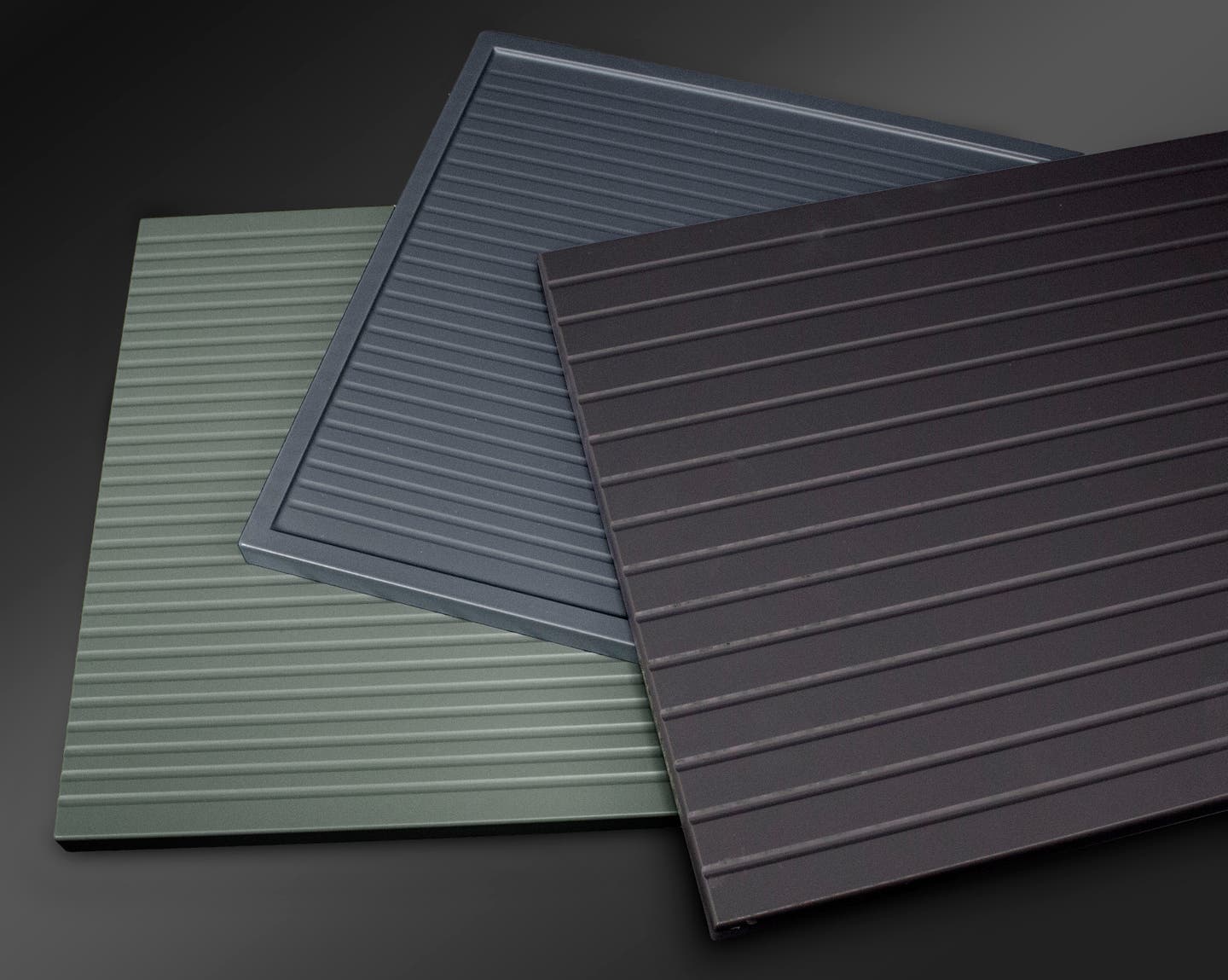

Missouri-based RSA Solutions understands that every custom woodshop has unique needs. The RSA team also knows that the software one chooses should fit the business model, and not the other way around. With that in mind, the company has a strong suggestion for small to midsize shops. helps casework and custom builders handle those time-consuming, one-off projects. It is designed to let woodworkers discover where the profit lies in custom jobs. It's a breakthrough program that engineers everything, on a single AutoCAD 3D platform. Yes, everything – case goods, reception desks, store fixtures, wall paneling, complex millwork and more.

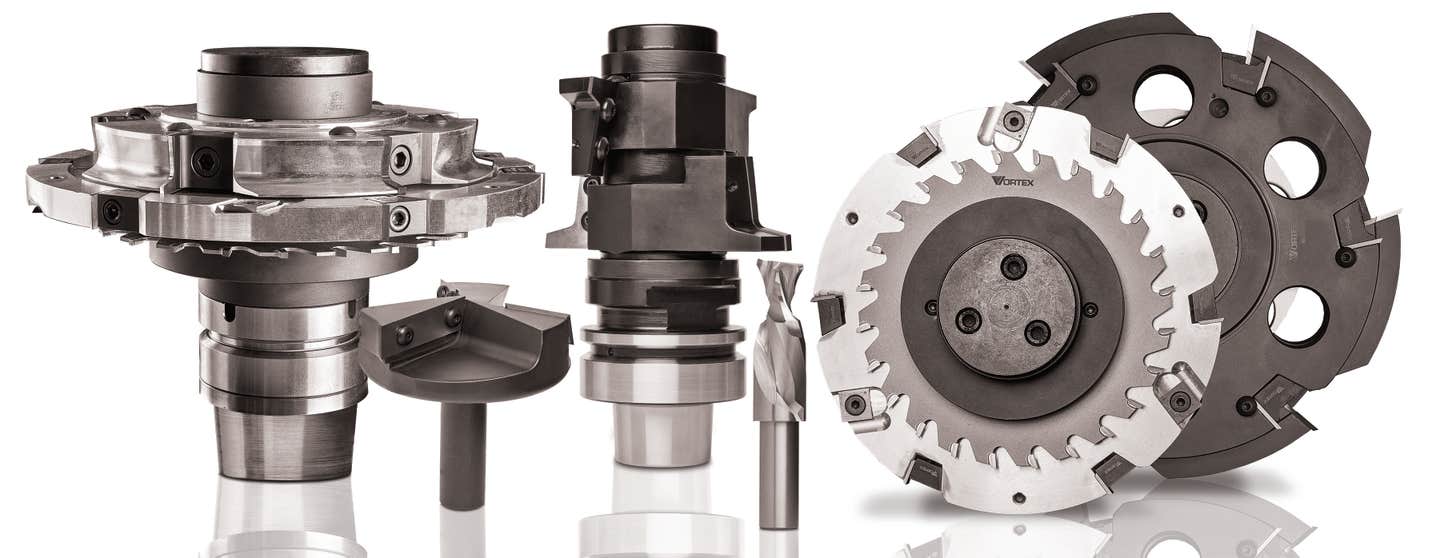

Even though most software packages cater to cabinets, a shop that's using multiple packages is paying too much in both time and processes. If your company is experiencing an abundance of shop capacity but a shortage of data to leverage that capacity, it may be time to take a look at woodCAD|CAM. It doesn't depend on a complicated library of never-ending formulas, and it's both intuitive and designed to simplify processes. For example, it will create 2D or 3D drawings that contain all the information needed for manufacturing. A user can easily create real time sections and exploded views of products, or dimension automatically with the touch of a button. woodCAD|CAM uses contour shape extrusion in a shadowbox to add parts, drawers, doors, buy-outs, all from scratch. Every article designed is parametric, with no lengthy formulas.

The Part Designer module also allows for building up non-parametric designs, one part at a time, and attaching them to other parts using proper joinery that can be selected by the engineer. The program outputs up to 5-axis machine code, if the woodshop's CNC equipment can deploy it. Part Designer lets the user add machining to parts while in 3D, and/or change joint associations between parts while in development. Contours of parts or assemblies can also be modified, simply by modifying the contour. That means there is no fumbling around in a spreadsheet to complete simple variations of construction.

All of the heavy lifting calculations, the CNC data, and the material/labor/work cell needs are done behind the scenes. There is no dependency on a library full of spreadsheets that must be referred to as you develop new products – no formulas, and no limitations on what you can create. Everything that’s engineered in Article Designer or Object Designer is fully parametric!

The bottom line here is that gives the user the ability to produce complicated one-offs and custom products graphically, where the only limitation is imagination. You can learn a lot more about woodCAD|CAM on the RSA Solutions website.

RSA SOLUTIONS

Phone: Shawn Maberry

(417) 682-5975

Email: maberry@rogershaw.com

Web: www.rsasolutions.us