Lockdowel Automatic Inserter With Auto Loading

Cabinet shops looking to automate Lockdowel clip insertion have a revolutionary new option available. California-based CNC Factory has formally introduced the new Scorpion LDR.

Cabinet shops looking to automate Lockdowel clip insertion have a revolutionary new option available.

California-based CNC Factory formally introduced the new Scorpion LDR at AWFS in July, but many customers are already reaping benefits from ownership. The machine allows either one or two woodworkers to handle up to four workstations, dramatically increasing the rate of milling, insertion, and ultimately assembly.

The company, a Visionary Award Finalist at AWFS, developed the new boring and insertion machine in response to customer demand. So it was no surprise that the booth in Las Vegas was filled with rapt audiences for every demo.

“Woodshops have been waiting a long time for a better solution for dowel insertion,” said Chris Corrales, CEO of CNC Factory. “So, we’re proud to have united with Lockdowel to provide exactly that in an easier, faster and more affordable machine.”

One of the biggest draws of the new Scorpion LDR is that this is the only insertion machine on the market that incorporates auto loading for casework parts. That makes the cycle a lot easier and less fatiguing for the operator, and that’s a concept the company has long espoused. For example, its Python XPR auto loading CNC machine was also designed for high output while being exceptionally user-friendly, and letting woodworkers avoid any heavy lifting.

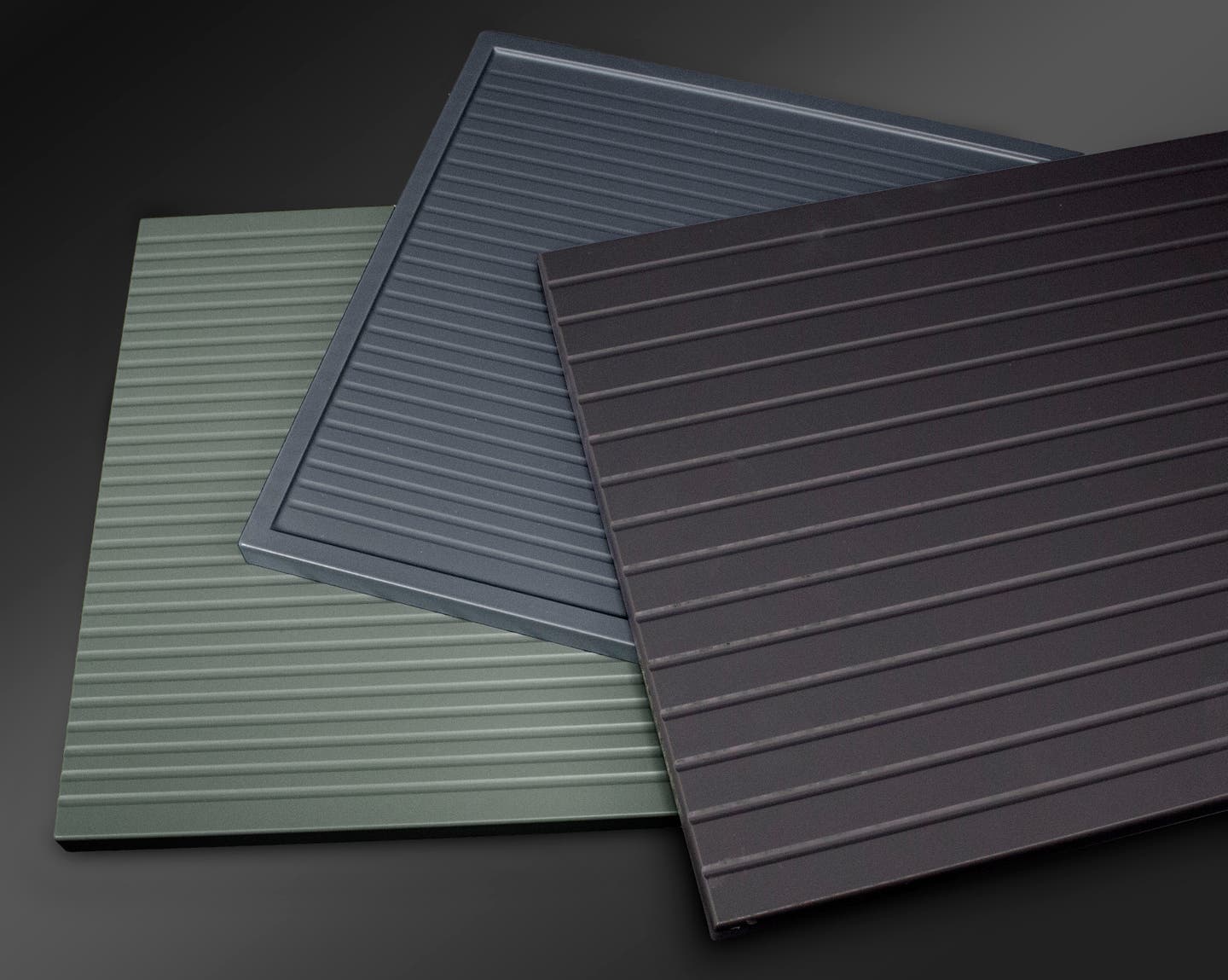

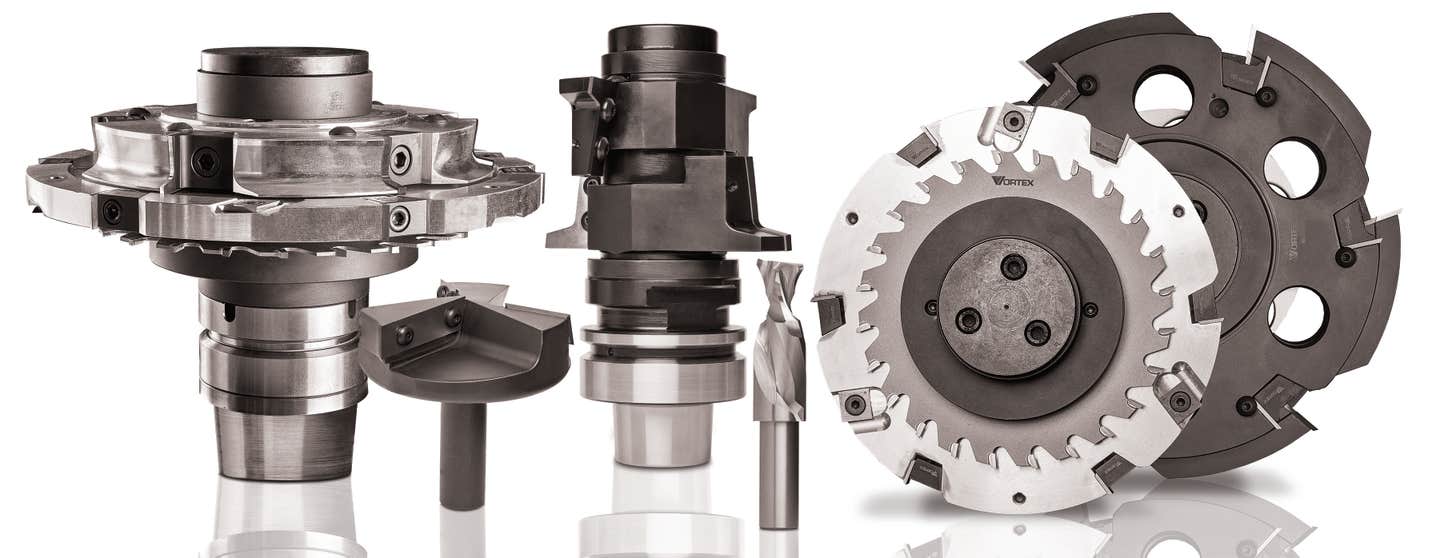

The Scorpion LDR works with all of Lockdowel’s e-clips and spring pins, plus H and Channel clips in either metal or plastic. It’s powered by an industry-leading Delta spindle inverter, and Delta servo motors.

The machine lets woodshops create a beautiful, seamless look on drawers, drawer fronts, closets and other casework by eliminating both the need for glue, the labor to apply it and set clamps, and the curing time. Lockdowel clips are an easy assembly solution: just snap or slide, and you’re immediately on to the next subassembly. CNC Factory hears a lot of testimonials about the way that these connectors can speed up cabinet and drawer construction.

“I’ve saved so much time and money with my LDR machine,” says one commercial woodshop owner. “I particularly like that it has four working zones, and automatic material loading. Plus, it’s equipped with the latest technology in laser guided robotic measuring, and there’s an advanced wireless barcode reader. But the best part for my shop is that one employee can use this, and produce a lot of product in a very short time.”

CNC Factory’s Scorpion LDR is fully integrated with the most popular software packages such as Cabinet Vision™ from Vero, plus Mozaik™, TopSolid’Wood™, SOLIDWORKS™, Microvellum™, Imos Software and more. And this is not just a generic boring machine, but a comprehensive solution that provides an integrated platform for growth in robotic lean manufacturing.

“The solid structure of this machine combines with third generation technology and material auto loading to present woodshops with a significant advantage when it comes to assembly,” said Corrales. “We built this machine specifically to reduce assembly time by 80%, and eliminate the time and effort involved in material handling. Now your employees can focus on quality and customers because of the faster production times it delivers.”

CNC Factory builds world class CNC routers, machining centers, edge-banders and thermofoil presses. The company’s goal is simple: to help customers achieve more in less time. It does this through innovative engineering, industry-leading products, factory direct support and training before and after installation, and direct pricing. The team at CNC Factory invites woodshop owners to spend a day at the California facility, to explore the possibilities of a win-win relationship

CNC FACTORY Inc.

(714) 581-5999

sales@cncfactory.com

www.cncfactory.com