Lockdowel Locks In Fast Assembly!

What if there was a way to build more product in less time with fewer people? Whether it’s cabinetry, furniture, closets, or drawer boxes, there’s a new assembly solution to…

What if there was a way to build more product in less time with fewer people? Whether it’s cabinetry, furniture, closets, or drawer boxes, there’s a new assembly solution to consider.

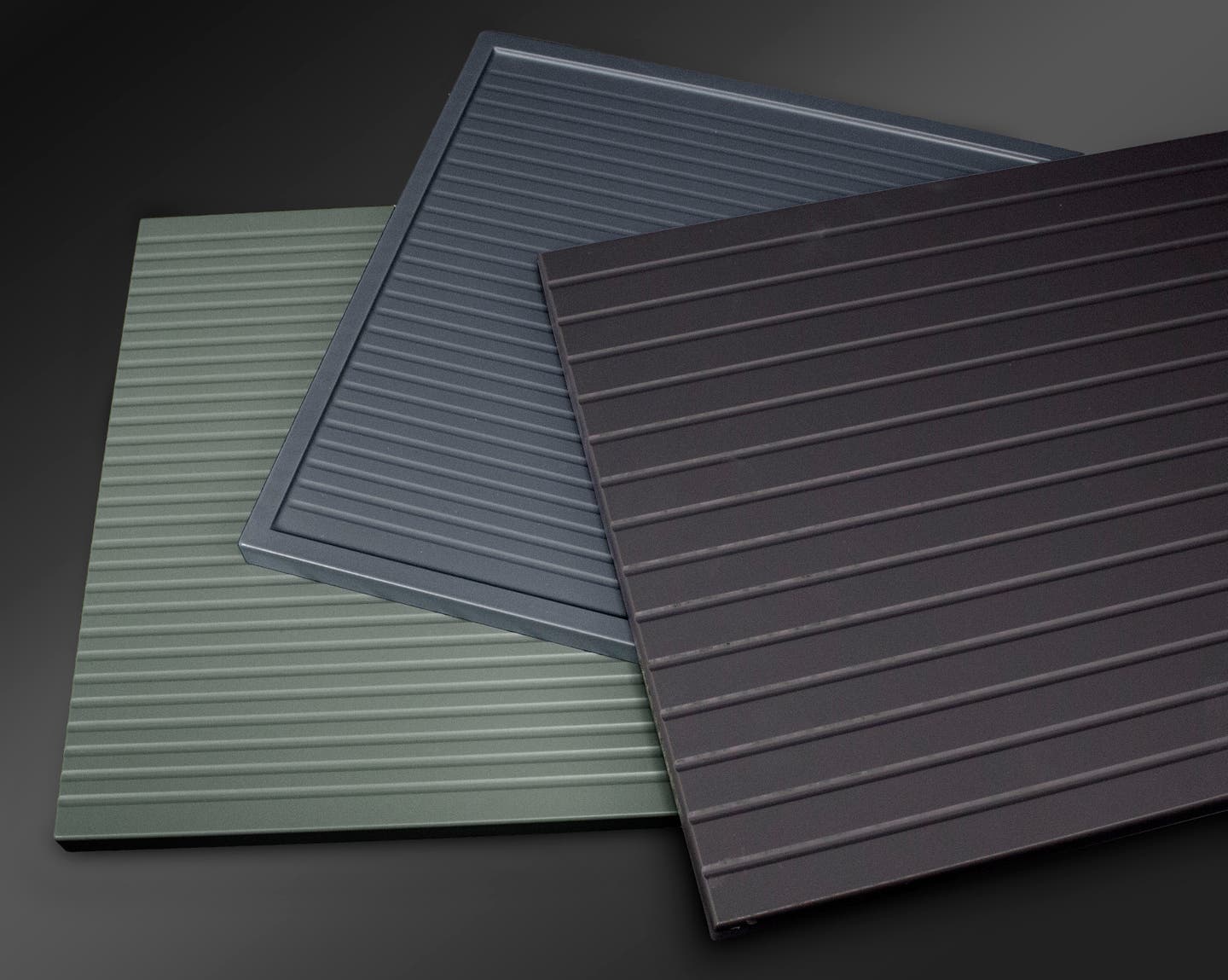

Lockdowel is an invisible joining system that can be either permanent or knock-down. The rapid assembly system uses simple CNC machining and clever hardware to create slide-together cabinets that require very little training to assemble – a huge advantage considering the difficulty of hiring and keeping qualified staff in the current labor market.

The company has also expanded its complete hardware solution to include One-Click 3D undermount or side-mount slides. There is no faster drawer slide installation in the industry.

The entire process is tool-free and glue-free, with no clamps or cure time.

Here’s how it works…

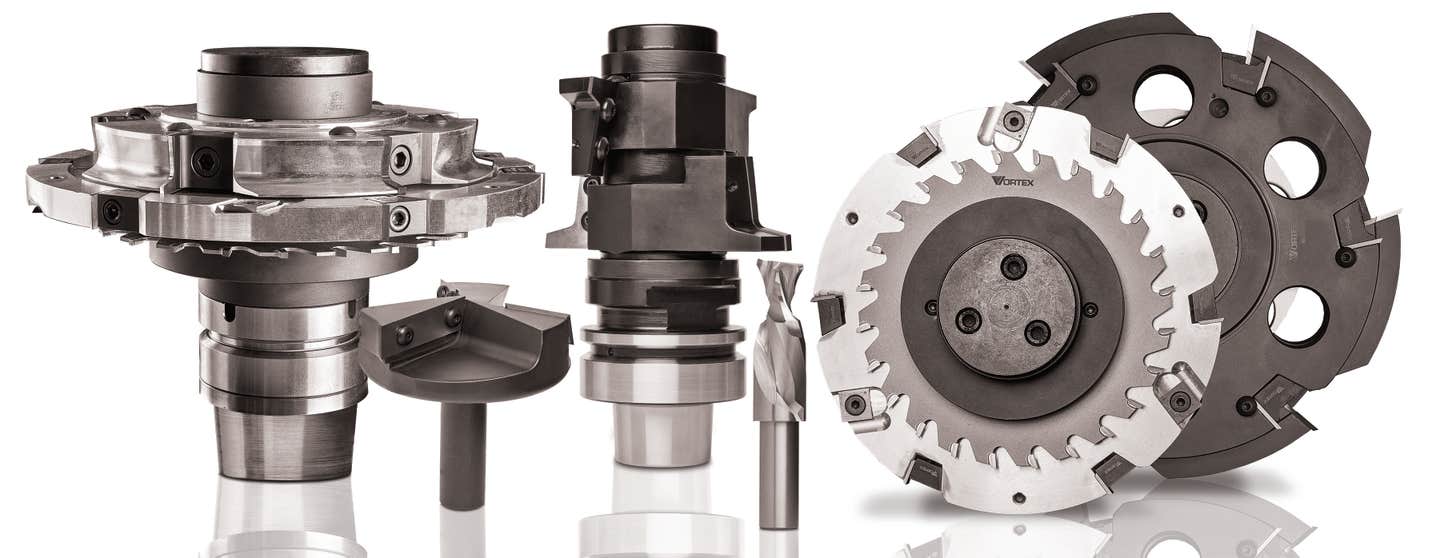

Lockdowel’s single fastener concept uses a keyhole slot designed to fit an engineered dowel. That’s it! Any CNC router can use the special router bit to mill the keyhole slots, and any edge-boring machine can be used for edge drilling.

There are two fastening options. The Channel Lock system uses only one fastener per joint and results in the fastest assembly in the industry. Multiple variations are available based on panel thickness and material. The solution allows for either assembly in your shop, or an RTA method that allows for flat-packing to the job site. Panels assembled with Channel Locks can also be disassembled any time for moving or replacement of damaged parts if needed.

The second option, the H-Clip, is a permanent joint that provides even greater rigidity, and cannot be pulled apart or disassembled.

Both fasteners use the same router bit, and both are invisible after assembly.

The Lockdowel system guarantees its fasteners are positioned correctly every time with precision holes and routes pre-drilled via CNC equipment. Products built with Lockdowel hardware have been independently tested to meet all ANSI/BIFMA test standards. It’s also the only fastener solution tested and approved by AWI for up to Duty Level 3 base, tall, and wall cabinets. Customer satisfaction is outstanding and returned goods are virtually eliminated.

The production numbers are impressive, too. For example, after switching to Lockdowel, Chad Shelton, Owner of Bella Innovative Modern Cabinetry in Indiana notes that his shop went from 25 cabinets a day to 135 – with only six employees.

Those numbers are possible because the Lockdowel system reduces assembly hours by 40% or more. The fasteners slide firmly into the routed slots using a friction fit. There is no end-panel cover up necessary, and the invisible fasteners create a tight joint and a high-end finished look. The precision system ensures the fasteners are positioned correctly every time, so the potential for employee assembly error and rejects is minimized. Every Lockdowel product was created following the same principle: To simplify manufacturing and assembly.

Lockdowel offers an Evaluation Kit as a first step for woodshops to explore the system. It includes a router bit, samples, and a ready-to-assemble demo unit to introduce woodworkers to this state-of-the-art fastening technology.

LOCKDOWEL INC.

Web: https://lockdowel.com

Email: info@Lockdowel.com

Phone: 866-389-5393