The Best Built CNCs Build the Best Cabinets

One of the most rewarding parts of building casework in the age of Industry 4.0 is opportunity.

One of the most rewarding parts of building casework in the age of Industry 4.0 is opportunity. Advanced technology provides us with a way to find a global solution to a local challenge. A woodshop owner can literally travel the world without leaving the office, and discover new ways to increase profitability and production. A prime example of this bounty is Limtech Industries, which is located in North Carolina and brings the best of global engineering and manufacturing to the doorstep of America’s woodshops.

Limtech's Asian factories design and build its products, meeting the company’s strident specifications at every stage from construction to configuration, features, and the brand name components used. All products are uniquely designed and built from scratch the Limtech way, and the result is a perfect meeting of quality and cost. Woodshops receive state-of-the-art engineering and support at affordable, reasonable prices. With a long list of satisfied customers who are more than willing to share their experience with shop owners, there’s something very comforting about the way that Limtech works.

And there are plenty of reasons that those customers love Limtech. For woodworkers who worry about Windows™, there’s the fact that the company only uses stand-alone PLC controllers that don’t rely on that platform. Customers never worry about PC crashes, software updates, or issues with proprietary software communications.

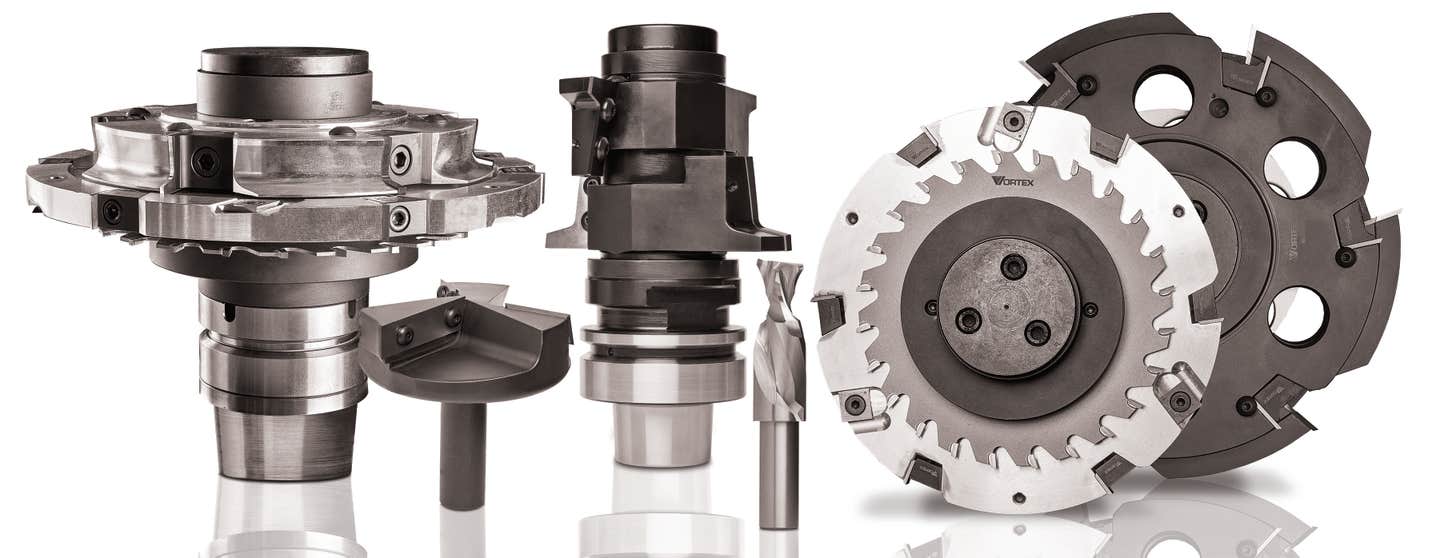

Limtech users also enjoy the security and confidence instilled by world class, brand name components such as HSD spindles and Fanuc controllers. Those parts are easy to source, which keeps maintenance costs down. And speaking of maintenance, the company configures its products with the industry's highest mechanical drive configuration, such as servo motor with ball screw, or with planetary gearbox and helical rack and pinion systems. This means that Limtech machines require low maintenance and have a simple service oriented design: a woodworker can replace most components or perform simple adjustments without requiring that a certified field service engineer is onsite.

That kind of solution is made all the easier because technical support on the company’s CNCs is… free! And after a woodshop buys a machine, its operator receives log in information to access a customers’ portal for general technical documents such as manuals and operating instructions.

There are three series of machines available. The Centaurus is the entry level industrial series. It enjoys many of the design and operating features of the larger Orion series in terms of reliability and serviceability, but it comes with linear tool changing stations instead of the onboard carousel tool-changer that’s on the Orion. The Centaurus is an excellent quality and very affordable machine with standard features and available options that are designed for nested base manufacturing, specifically with cabinetry and closet systems that take advantage of in-line 32mm line boring in the X and Y axes.

The larger Orion series is the company’s flagship, and it is “built like a tank” from its table frame construction to the size of the components used. It has three linear guide bearings for each guide rail on all three axes. Plus, it comes with a FANUC controller including the monitor and keypad, plus servos, drivers, amplifiers and PLC, and it’s backed by a 2-year warranty from Fanuc America. And the Pegasus series shares all the same features and build specs as the Orion, but its larger frame format allows it to be fully customizable regarding table size, spindle, tool changer and Z-stroke configurations. It’s the ideal machine for woodshops looking for a heavy duty machine with desirable, custom options.

With Limtech, it's not where the products are built, it's how.

LIMTECH Industries

Website: www.limtechindustries.com

E-mail: Info@Limtechindustries.com

Phone: (704) 200-9964

Video: https://youtu.be/z2tqYRqsdew