The U.S Coatings Market is at a Crossroads

This is a unique time to be in the wood coatings industry in the United States. Now more than ever, American finishers and woodshop owners are finding that they need to juggle price and quality to find the best answers.

This is a unique time to be in the wood coatings industry in the United States. Now more than ever, American finishers and woodshop owners are finding that they need to juggle price and quality to find the best answers. Consequently, they’re researching options like never before, and because of that the team at Milesi is fielding more and more questions about 2k urethanes over conversion varnishes. Milesi is a brand of the IVM Group, which is one of the largest and most influential wood coatings manufacturers in the world. And the answers those shop owners find are surprising a lot of people.

2K urethanes are actually more user friendly.

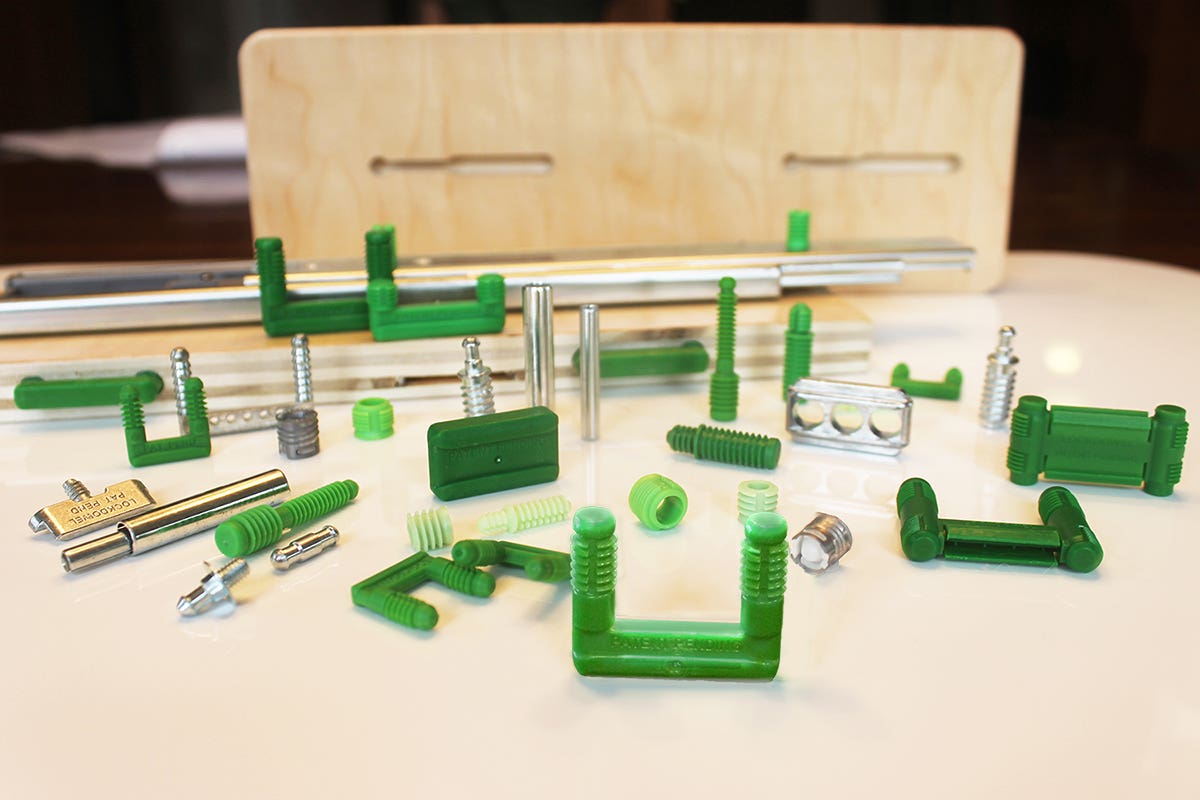

With typical industry standard varnishes, a shop sees small catalysation ratios from 10% to as low as 2%, and some coatings manufacturers have one catalyst for the sealer and a different one for the primer and so on. Until now, this meant that finishers had to keep spreadsheets and break out their calculators just to be able to mix product correctly. Conversion varnish catalyzation ratios are crucial, which requires measuring as exactly as possible. If one goes too easy on the catalyst, the product will not dry properly, or even not at all. And if one adds too much catalyst, the product can acid bloom or crack.

On the flip side, 2k urethanes tend to have simpler ratios such as 50%, 25%, and 10%. This makes it faster to get product ready, without having to learn algebra just to spray a job.

Some finishers still think that conversion varnishes have an advantage over 2k urethanes when it comes to pot-life. The going rate on CV pot-life is typically 24 hours for clears and 8 hours for pigmented. (There are, of course, exceptions to this.) Coatings factory reps have been saying for years that shops can leave product in the pump overnight and pick it up the next day and spray. But nobody can realistically do that and still put out a consistent finish. Most woodworkers will set up in the morning, spray until lunchtime, and after lunch they’ll stir the coating, re-circulate the pump and start up again. But with urethanes, they can simply mix product for the morning and spray. After the break, product can be quickly mixed for the afternoon. Bottom line: both methods use the same amount of time. Typical 2k urethanes pot-life on clears is 4-6 hours (up to 24 hours on some), and 2-6 hours on pigmented, depending on the product.

There’s also a great debate, and some misinformation, about formaldehyde and isocyanate. There are actually two types of isocyanates in European 2Ks – bonding and free. When a woodworker is mixing 2k urethanes, the hardener typically has resin in it as well. So, when the user is mixing part A to Part B, they’re virtually mixing with bonding isocyanates (which is the one that’s ‘not bad’). Free isocyanates, on the other hand, are considered harmful. Formaldehyde is released as conversion varnish starts the drying and crosslinking process. It will stay in the film of the coatings for weeks as formaldehyde is released into the atmosphere.

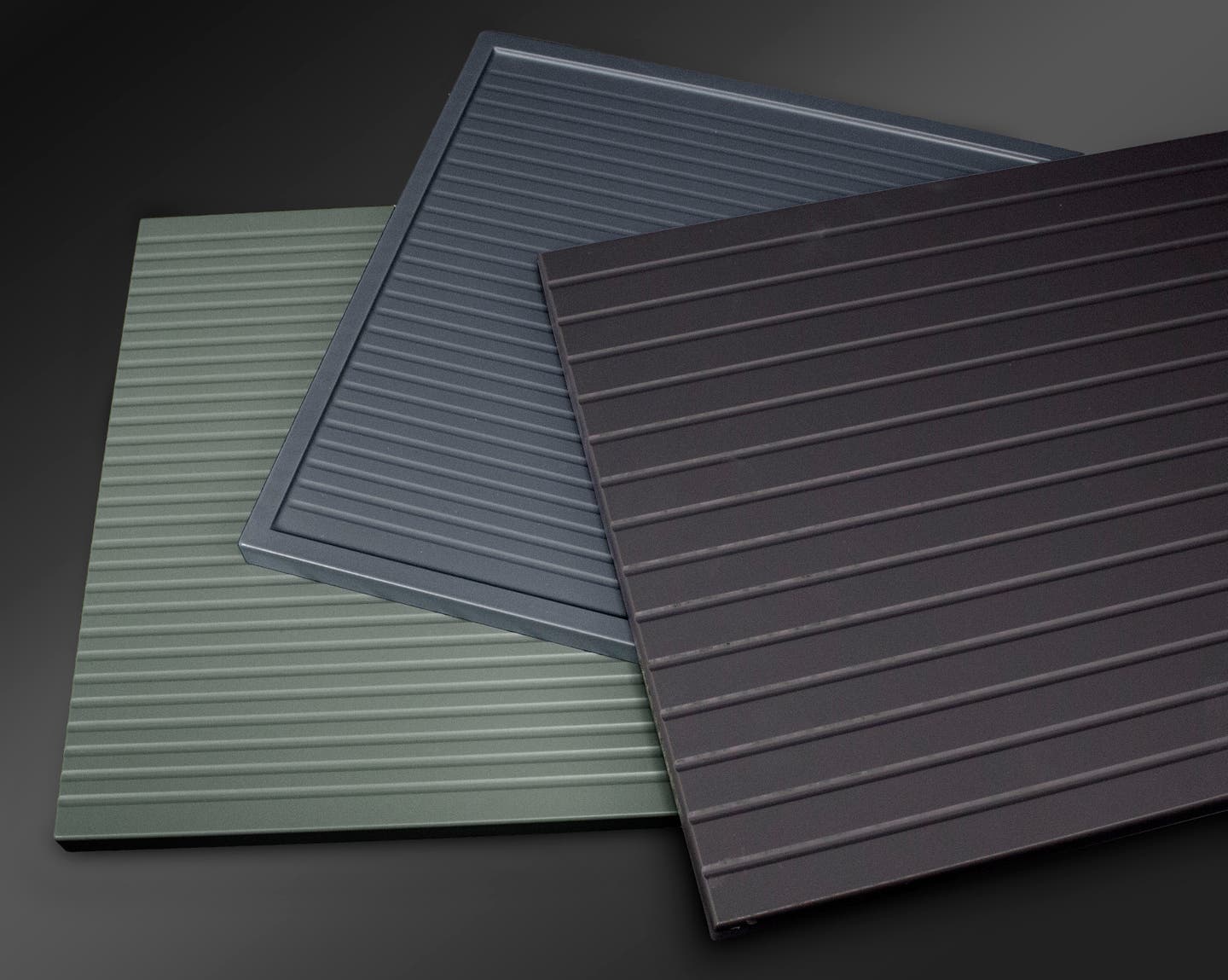

The experience of European coatings is reaching Stateside of late, and it’s catching the attention of both finishers and shop owners. They’re learning that 2Ks are quickly bridging the gap, and soon will replace varnishes as the standard for high-end cabinetry, millwork and furniture finishing.

Visit Milesi online, and discover how experience pays.

Milesi Wood Coatings

LinkedIn: https://www.linkedin.com/company/milesiwoodcoatings/

Facebook: https://www.facebook.com/Milesiwoodcoatings/

E-mail: milesi@milesi.us

Website: http://www.milesi.us

Video: https://youtu.be/agAHTml0q8k