The Ultimate Workbench Isn’t a Choice – It’s a Necessity

Once in a generation somebody has an idea that changes the fundamentals of an industry.

Once in a generation somebody has an idea that changes the fundamentals of an industry.

For thousands of years, woodworkers have been using dogs in holes and clamps around the edges of benches to hold work. Even the earliest Roman workbenches from AD 79 used that system, and little has changed since.

Now, MICROJIG’s Ultimate Workbench has revolutionized how work is held, and it does so in a way that artisans can truly appreciate. That’s because the system not only fastens work anywhere, but it also lets the woodworker design and build a bench to meet their specific needs!

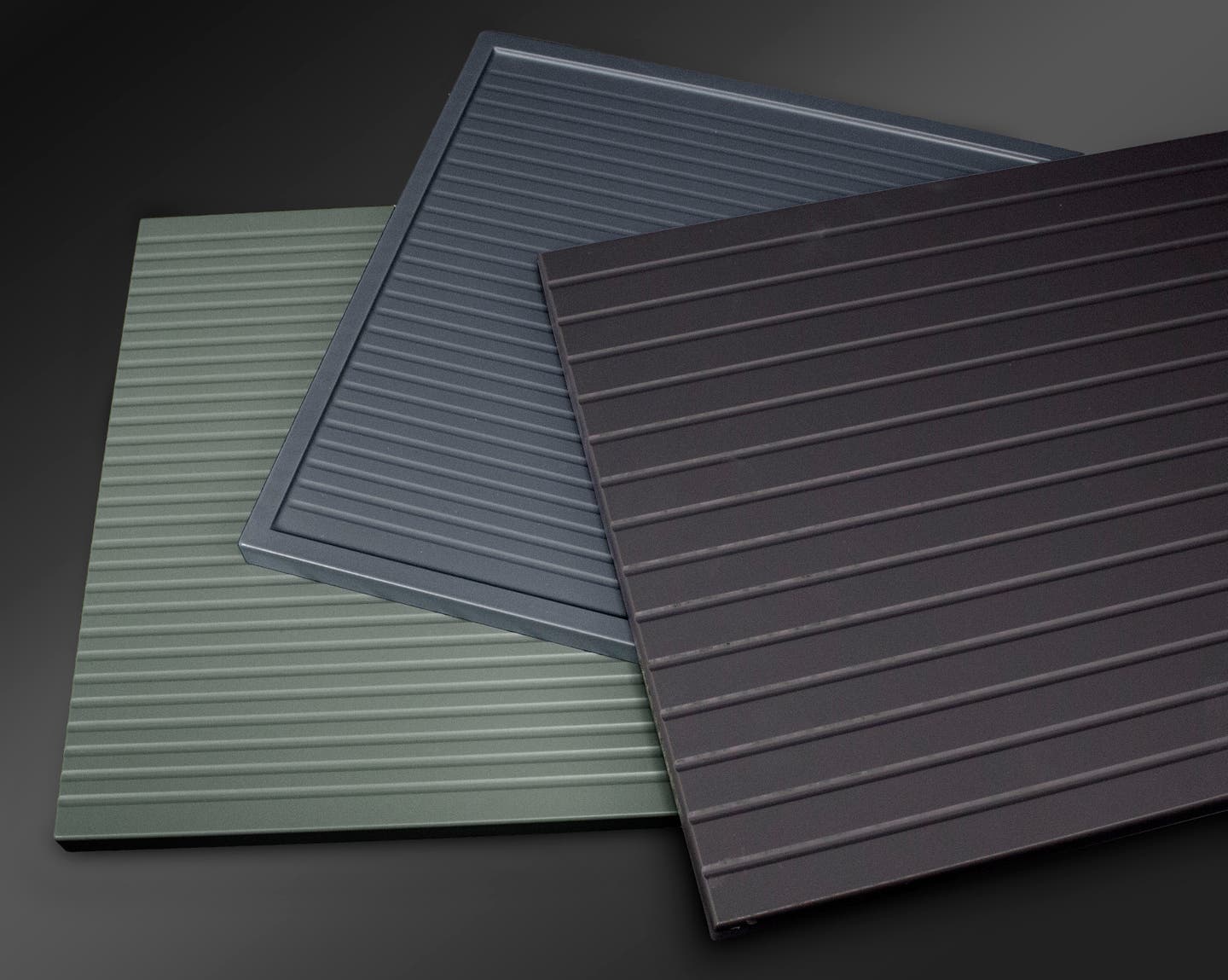

MICROJIG uses another ancient concept, the dovetail, to deliver this unheard-of versatility. At the heart of the Ultimate Workbench system is a grid of MATCHFIT™ Dovetail Tracks that accept the company’s innovative MATCHFIT Dovetail Track Clamps® and Hardware. With any standard 1/2”, 14-degree dovetail router bit, a woodworker can create rout clamp tracks, eliminating the need for expensive aluminum tracks. It’s an entire system designed to provide all the functionality of T-track and its accessories, but at a fraction of the cost. The grooves offer a way to slide the clamps across the top of the bench and locate them virtually anywhere they’re needed. Instead of a series of static bench-dog holes with fixed locations, the grooves offer a fluid, flexible and incredibly adjustable way of fixturing. The woodworker can even micro-adjust clamps by fractions of an inch along the grooves as needed – something you can’t do with dog holes. The bench also accommodates shop-built jigs, fences, and stops that can be secured at any angle, which is why MICROJIG calls it the MATCHFIT 360 clamping system. Plus, the plans call for horizontal grooves partway down the sides of the bench too, so workpieces can be fixed in a vertical orientation for working on their edges and ends. And because those two grooved surfaces are at 90 degrees, a woodworker can simultaneously exert clamping pressure down (to keep assemblies flat) and across (to keep edges tight), which is ideal for projects such as cutting boards. Plus, unlike traditional end vises, there’s no screw or guide bars (rods) to get in the way, so parts taller than the bench can be secured vertically with ease.

Speaking of tall, the Ultimate Workbench is built on an adjustable height table (available from The Home Depot, item HOLT5202BJ2, $249) that can be raised and lowered from 26” to 39”. Its quick crank adjustment and locking casters makes it ideal to use as an outfeed table for every machine in the shop. And the bench can cozy up to the band saw and provide a huge support table with a fence for cutting panels and sheet stock.

The MATCHFIT 360 system allows a woodworker to build a bench to whatever dimensions best suit his or her needs. Or one can just rout the dovetail groove pattern into an existing workbench and equip it with some MATCHFIT Dovetail Clamps. Again, versatile and customizable are the keywords here.

There’s one more innovation, too. Those dog-holes – well, the Ultimate Workbench does have some, but they’re not doghouses. Instead, they’re a little oversized so that MATCHFIT Dovetail Clamps can be inserted through them from the underside, to hold low profile stops and perform other clamping functions. That means when a woodworker is sanding or planing a standard board, the stops holding it are thinner and don’t get in the way.

It’s time to rethink that beautiful but cumbersome old beechwood bench.

It’s time to move past millennia of awkward fixturing.

It’s time for MICROJIG’s Ultimate Workbench.

MICROJIG

Phone: (855) 747-7233

Email: support@microjig.com

Web: www.microjig.com