Woodshops Find All the Answers in One Place

Wouldn’t it be nice to find every major machine you need in a single catalog?

Wouldn’t it be nice to find every major machine you need in a single catalog? Think about the advantages of dealing with one resource that supports sales, professional installation, customer care – and a tech support team that understands how these machines will work together to help you make the best cabinets and furniture.

California based Castaly Industries does exactly that. Whether you need to size casework components, bore shelf holes, mill grooves, raise door panels or bore for hinges, they have you covered.

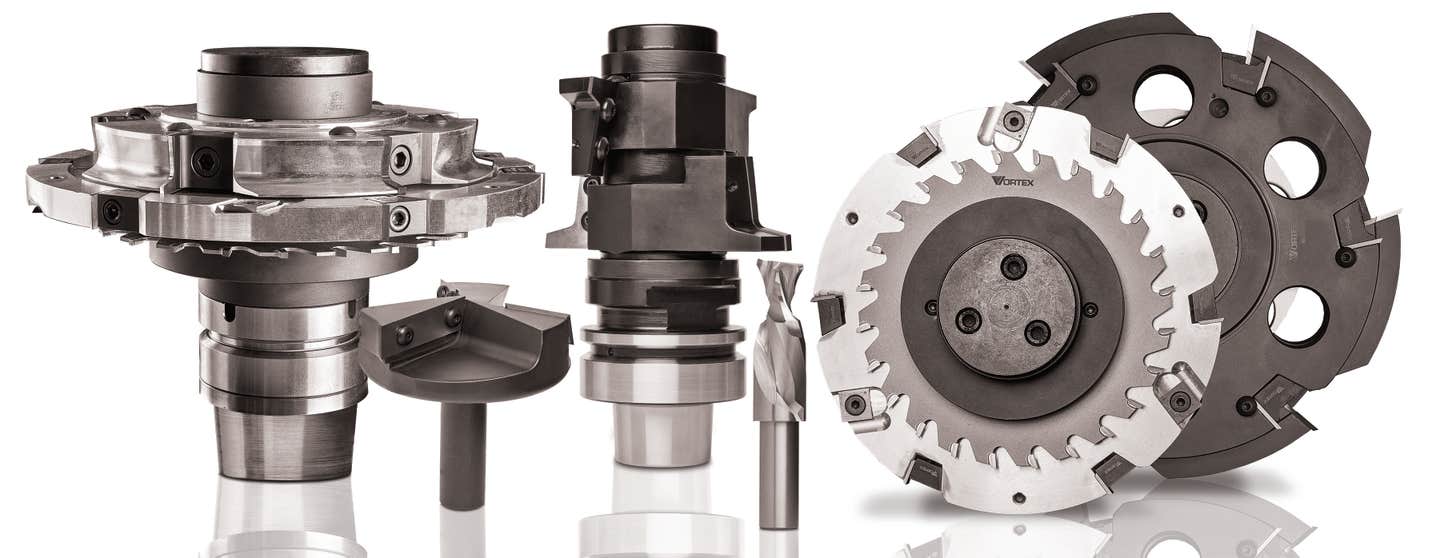

Take, for example, the Pro-510 CNC Router. This complete panel processor has a moving gantry over a 5’x10’ work area, an 8-station tool changer, automatic infeed with a scissors lift, and unloading with a conveyor belt. The drive system is all AC servo, and there’s a conversational Syntec controller. The Pro-510’s air-cooled 12.8 HP (9.6 KW) HSD spindle has dust-free bearings and an auto frequency brake. An optional CAD/CAM system can create and edit part programs, and then send them to the machine for easy cutting. DXF files can be imported, modified and even edited from here, to create G-code.

With the panels cut, the woodworker can take them to the BR-9633CNC-6S from Castaly. This CNC boring and grooving powerhouse has a pneumatic hold-down cylinder and can work on all six facets of a part. There’s a 4.6 HP (3.5 KW) air cooled spindle, thirteen vertical and four horizontal heads, and an automatic push and position system for in-feeding, processing and out-feeding. It can mill all the grooves and holes required for assembly. Its CNC controller is set up to accept standard G-code programming formats, along with on board conversational applications. And its rigid steel frame construction has been stress relieved prior to finish machining, to provide the utmost in reliable accuracy and repeatability. This, too, is an AC servo machine where all axes are driven by brushless, high-torque motors. The power requirements are 220 Volt, 3-phase and there’s a 5 KW inverter on board.

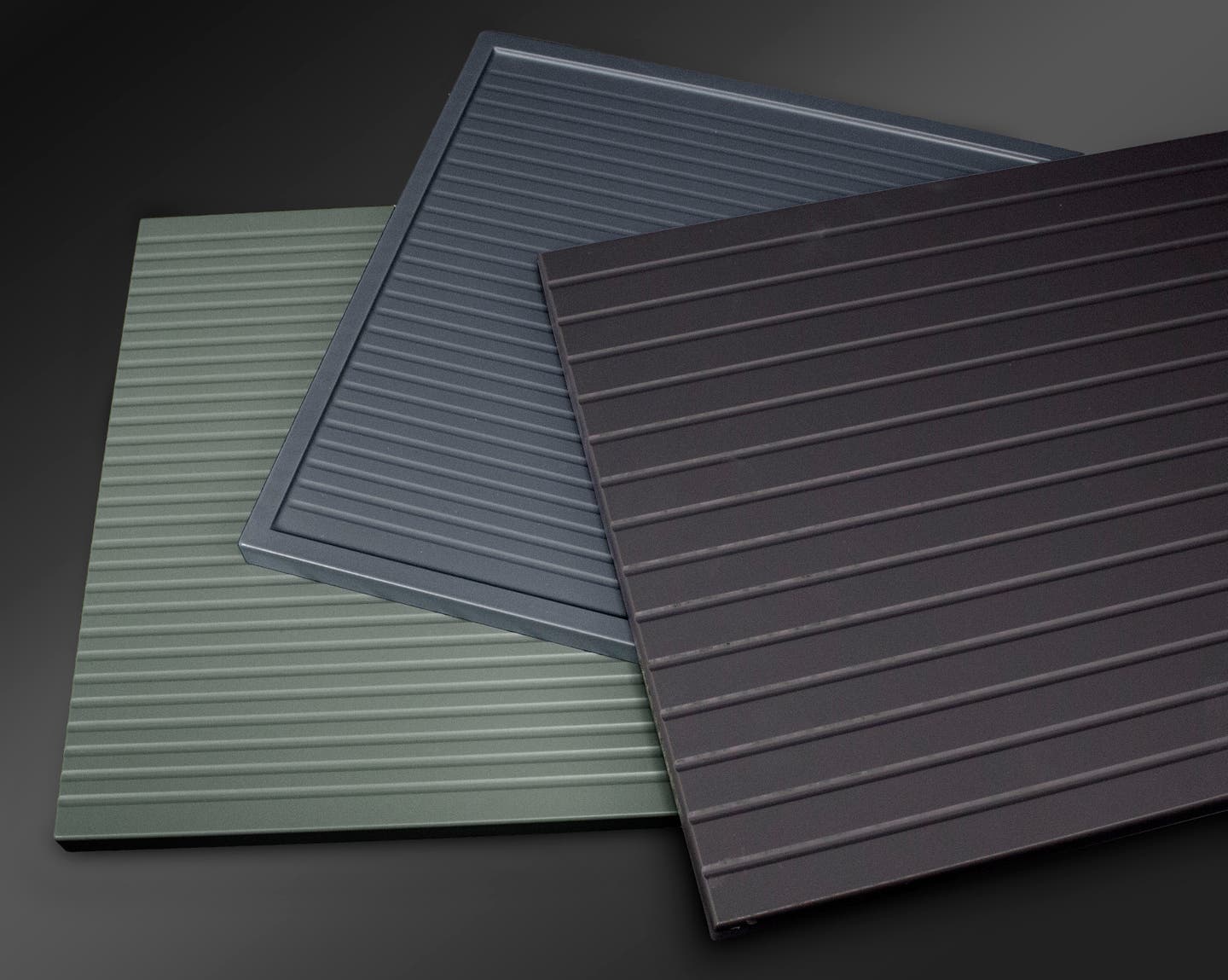

And with the boxes built, Castaly’s Lobo brand 55” automatic raised panel door shaper (CS-55PAAU) comes into play. Designed to create all the parts for raised-panel doors with a single spindle shaper without changing knives, it brings affordable mass automation to milling door rails, stiles and panels. It has a 6" high, 1-1/4” diameter, stackable spindle with three pneumatic stops, so set-up is fast and easy. Built to work, its rigid construction includes a heavy sheet metal frame and a cast iron table and base. The 55PAAU is equipped with a 10 HP main motor – large enough that there’s no need to pre-cut arches or ovals. The right-left movement of the bearing and rail guided table is hydraulic powered by a 1 HP pump, and the in-out travel is pneumatic. This latter allows for better sensitivity when following templates, and thus more accuracy. This machine can also handle chair legs, furniture parts and other production tasks.

When it comes time to mount the doors, Castaly’s double drill hinge borer (BR-02HG) can bore one, two or four hinge pockets in a single pass. In fact, it is capable of using multiple drill heads to deliver any drilling configuration, and its foot operated pedal leaves the operator’s hands free to speed the work along. Powered by a pair of 1-1/2 HP spindle motors, this machine is also available in a four-head configuration.

Located in Los Angeles, Castaly Industries offers a full line of reasonably priced, exceptional quality CNC routers, laser engravers, edge banders, boring machines, panel saws and dust collection blowers.

CASTALY Industries

Phone: (626) 369-6500

eMail: info@lobomachine.com

Web: www.cncroutergroup.com

www.castalymachine.com

www.lobomachine.com